At the Oregon Center for Electrochemistry, University of Oregon students and faculty members research how energy is generated, stored, and transported. And they’re leading the way for sustainable energy.

RELATED LINKS

Lean, green, and innovative, the OCE also prepares students for success in a field that’s in high demand for industry. Ultimately, these UO faculty members, students, and alumni are helping address climate change.

Thanks to a $5 million gift from Gordon and Betty Moore, the future of the OCE—which started in 2019—is looking bright. Gordon Moore is cofounder of Intel Corporation, a company also known for innovation-creating, world-changing technology.

“We are very grateful to the Moores for this generous gift,” says Patrick Phillips, interim president of the university. “The OCE's collaborative, forward-thinking work reflects the shared purpose and community of our university and capitalizes on our strengths to fill a critical national need.

"These faculty members are leading the way for sustainable energy, through their research and by empowering students to start careers aimed at making a real difference in the world. Thanks to the Moores’ gift, we continue to build faculty strength in this area and broaden the UO’s impact through efforts such as our Environment Initiative.”

Energy is central to everything we do, says Shannon Boettcher, an alumnus and professor in the Department of Chemistry and Biochemistry, and the OCE’s founding director. “Electrochemistry is the key to developing a sustainable economy, reducing carbon in our atmosphere, and mitigating climate change.

“Gordon Moore is certainly one of my heroes, and we hope to make Gordon and Betty proud of this investment. It amplifies everything and allows us to think bigger.”

Thinking bigger, says Boettcher, means attacking the most-important science problems, translating discoveries into patents, startups, and commercial products. It means expanding industry connections and launching more student careers. Ultimately, Boettcher hopes, it will all add up to widespread change—in our economy, industry, policy, and technology—that stops climate change in its tracks.

Electrochemistry researchers study the relationships between chemical change and electricity. If a chemical reaction creates electricity, or vice versa, that’s electrochemistry. Electrochemists explore how to make better batteries (and reuse and recycle them). They study devices that convert electric energy into green hydrogen that could fuel trucks, ships, and planes—and produce sustainable chemicals, products, and fertilizers.

They seek ways to create better, lower-cost catalysts, fuel cells, and medical and environmental sensors. Electrochemists use electricity to deposit metals on structures as large as bridges and as small as the near-atom-scale wires inside of computer chips. They devise ways to stop corrosion, recycle metals, and clean water. Yet advanced training in electrochemical science and technology is sorely lacking, says Boettcher, because it doesn’t fit neatly into a single traditional discipline.

FINDING SOLUTIONS

Wind, solar, and wave energy is intermittent and difficult to store and transport. Alternative fuels like hydrogen aren’t much of an alternative if they are produced from coal and natural gas. And many current industrial processes, which account for approximately one-third of US energy consumption, are difficult to convert to run on renewable energy.

The National Science Foundation recently awarded the OCE with funding for its Center for Interfacial Ionics, and they’re exploring how ions transfer into solids—a fundamental action for batteries. The researchers are also using bipolar membranes to separate water into acid (protons) and base (hydroxide). These can be used to capture carbon from the atmosphere, deacidify the ocean, and create more efficient industrial electrochemical processes.

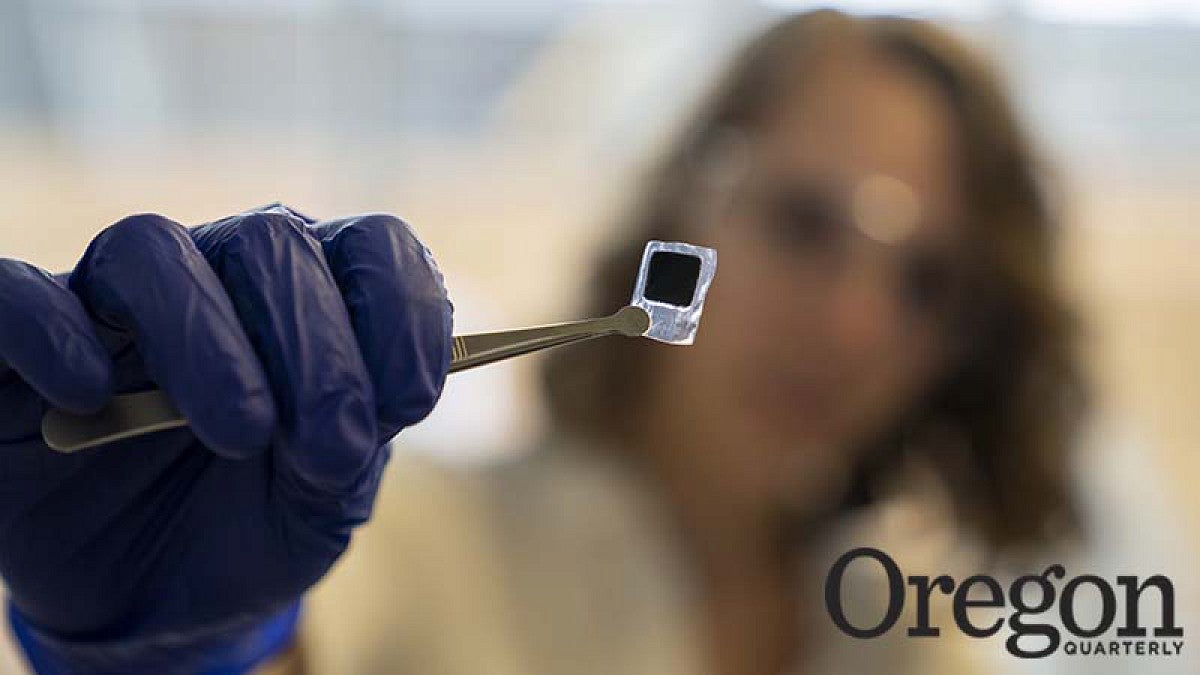

For another project, they use sunlight to drive photochemistry, effectively combining a solar cell with an electrolyzer. The goal: to develop a device that generates green hydrogen using only water and sunlight, at a low cost—and a massive scale.

OCE research involves faculty members at the UO and from around the world, as well as large corporations and small startups. Students play key roles, gaining professional experience while participating in groundbreaking—and industry-changing—science.

“My research has a very clear societal impact that aligns with my passion and my goals,” says PhD candidate Grace Lindquist. “We have electrolyzer companies reaching out to us to advise them on technology and help them bring products to market.”

Lindquist studies electrolyzers that split water molecules into hydrogen and oxygen. Although industrial electrolysis is commercialized, it is far from perfect. Lindquist’s work is helping companies produce hydrogen in ways that are more efficient, economical, and sustainable.

Industries at the vanguard of the green revolution desperately need employees with fundamental science and engineering experience and professional training, Boettcher says. The OCE ensures students have both, a key strategy for accomplishing a goal that’s simple but bold: become the best place in the world to get educated in this crucial area, helping transform industry—and the world.

APPLYING ACADEMICS, LAUNCHING CAREERS

“I feel like I’m making a difference,” Fortiner says. “This is helping speed up the transition to clean energy and solve the climate crisis.”

Redwood Materials, in Nevada, is not only the country’s biggest lithium-ion battery recycling operation, but the only company in North America that is scaling up a process to

Battery recycling offers promise for conserving rare materials, Davtians says, while reducing both the amount of raw materials extracted from the earth and the number of batteries that end up in landfills.

“The ultimate mission is to have zero waste and close the loop on limited raw materials such as lithium, nickel, and metals becoming more precious as the electric vehicle world starts ramping up,” Davtians says.

These batteries enable renewable energy by providing electricity when the sun isn’t shining and the wind isn’t blowing. The company also works to manufacture batteries from abundant materials readily available throughout the world, like air and iron.

“I couldn’t be happier with the UO program,” Paz says. “Electrochemistry is my passion. Companies like Form Energy appreciate a robust background in electrochemistry, and the training I received at the UO put me one step ahead.”

VENTURE PHILANTHROPY

The Moores’ gift is like an investment in a startup, Boettcher says. But rather than a business, they’ve provided seed funding for a center of discovery, learning, and innovation led by a collaborative team of faculty members.

In many ways, the OCE also reflects Intel’s salad days. Both started on a shoestring budget with ambitious aspirations. And in both cases, the teams that started them defied convention to create a better way.

“As a startup, we must be clever and cost-efficient,” says Boettcher, who joined forces with UO and Oregon State University colleagues to start the OCE. “We’ve been smart about growth and leveraged our integration of teaching, innovation, and research. We spend money dreaming up new ideas and implementing them, not on administration.”

Boettcher grew up in Creswell, a small town near Eugene where he spent summers working construction and baling hay. While his mother earned her PhD in biochemistry at the UO, his father ran a computer repair business out of their country home.

This combination of technology, chemistry, and hands-on work formed a solid foundation for Boettcher’s future teaching and research. He studied chemistry and physics at the UO, graduated in 2003 as a member of the Clark Honors College, then attended graduate school at UC Santa Barbara.

Gordon Moore also grew up in a small town: Pescadero, California (even smaller than Creswell), where his father was the county sheriff. He became interested in science at an early age, conducting chemistry experiments in the family garage.

Moore studied chemistry at San Jose State, transferred to UC Berkeley, then earned his PhD at the California Institute of Technology, where Boettcher later had a stint as a postdoctoral researcher.

In addition to helping launch the world’s largest semiconductor company in revenue, Moore also created the famed technology tenet that bears his name. Moore’s Law addresses the exponential increase of transistors in a computer chip over time.

Intel introduced the first commercial microprocessor and created a silicon foundation for the personal computer revolution. Intel also transformed how people did business. Egalitarian, productive, and obsessed with performance, the company’s founders embraced meritocracy and eschewed the wasteful executive perks and vertical organization charts of 1960s corporate culture. Boettcher and his colleagues have created an ecosystem of innovation that in some ways resembles a high-tech startup: efficient, collaborative, and laser-focused on outcomes. The Moores’ flexible gift will be used for faculty hires, student scholarships, shared instruments, and new projects.

“This seed capital will have long-term impact because we can invest it in ways that generate additional resources, returns for industry and society, and graduates who go on to work for innovative companies,” says Boettcher.

“People won’t give up energy, so we need new ways to generate, store, and distribute it. And we can’t wait. Making alternative energy work is the only way to solve climate change without crashing civilization.”

—By Ed Dorsch, BA ’94 (English, sociology), MA ’99 (journalism), staff writer for University Communications

—Photos by Chris Larsen, University Communications