My mom always said, “Jimmy, whatever you do, do it the best you can. If you don’t succeed, at least you did the best you could.”

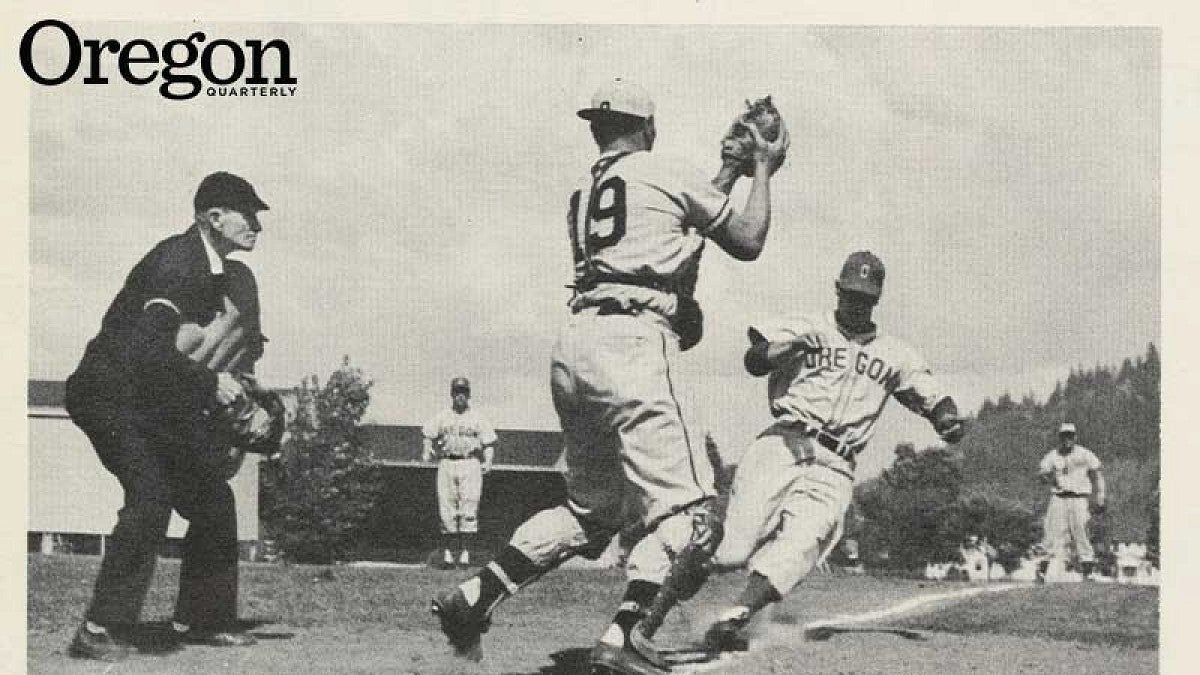

I love baseball. When I was 14, we were listening to the Boston Red Sox playing the St. Louis Cardinals and I took an attachment to Boston and said, “Dad, someday I’m going to be a catcher and play for Boston in Fenway Park.” At Oregon, I was a good hitter and had a good arm. In May 1953, Mother’s Day weekend, coach Don Kirsch awarded me the Emerald Award for citizenship, scholarship, and athleticism. When I received the award, I went into the stands and gave it to my mom and told her, “It was your coaching that gave me that trophy.”

I was signed as a catcher with the Red Sox and they shipped me to Roanoke, Virginia, and the old Piedmont League. But high blood pressure and high heat forced me to give up my dream of professional baseball. It was a hard decision, but I had to do it. I was 21 years old. I didn’t want to have a heart attack and I didn’t want to have a stroke. I didn’t want to die.

I had played semipro baseball for Archer Blower and Pipe of Portland—they built low-pressure air conveyors to suck up sawdust and shavings for the wood products industry. I called August Archer and said, “Can I visit you? I need to figure out what I’m going to do with my life.” He said, “If you want to learn the business, you’re going to have to start as an apprentice and work your way up.” I said, “Let’s go for it.”

I learned to build and install equipment. Another company was selling all these high-pressure pneumatic conveyors. The pulp and paper mills needed wood chips from a sawmill blown into a railcar to be taken to a mill to make pulp and paper. It was a wide-open field!

I left in 1967 and started my own company. My system was based on pounds per square inch, I said, “I’m going to name my company ‘PSI.’” That was a no-brainer.

In 1971, Roseburg Forest Products owner Ken Ford wanted a 1,000-ton-per-hour pneumatic conveyor to load chips into a ship going to Japan. The system he was using peaked at 565 tons an hour. It didn’t take a genius to figure out if I put the feeder at an elevation above the ship and “shotgunned” the chips down into the hatches, I could do better.

We put the feeder at a 55-foot elevation in a tower. On the second hatch of the first ship, we broke 1,000 tons per hour. That was a piece of cake. We average well over 2,000 tons per hour today with the same equipment. It was one of the world’s biggest air conveying systems. The longshoremen nicknamed it, “the Monster.” Today, we do business with Georgia-Pacific, Weyerhaeuser, International Paper, all the big blue-chip companies.

I’ve had a very exciting life. I guess I’m competitive. My mom always pushed me to do the right thing. She always told me she was proud of me, that I was willing to take on a challenge and do the best I could.

—By James “Jim” Livesay, BS ’53 (physical education), owner of Lake Oswego-based PSI Conveying Groups, as told to Matt Cooper of Oregon Quarterly